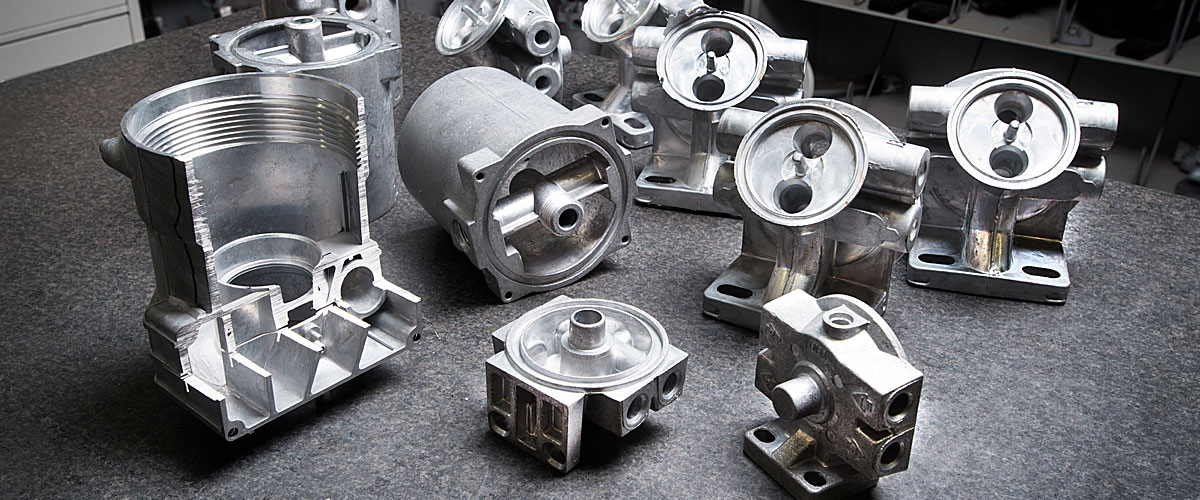

SR Enterprise the major producer of Aluminium Die Casting in most normal sizes to meet customer’s specific needs. We not only highlight on the quality, we also concentrate on the Aluminium Die Casting Machine.

- High operating temperatures

- Outstanding corrosion resistance

- Lightweight

- Very Superior durability and strength

- Great stiffness and strength-to-weight ratio

- Outstanding EMI and RFI shielding properties

- Outstanding thermal conductivity

- High electric conductivity

- Great finishing attributes

- Complete recyclability

Aluminium Pressure Die Casting strength, corrosion resistance, and heat dissipating properties provide mechanical designers significant benefits. Along with our proprietary Thin Wall Aluminum Technology has made aluminum die casting an alternative for even more software.

Have a look at our additional die casting tools .

Benefits of Aluminum Die Casting

Among the most crucial advantages of Pressure Die Casting Machine is the fact that it generates lighter components –with much more surface finishing choices than other die cast metals. Aluminum may also withstand the maximum operating temperatures of all of the die cast metals. Additionally, cast aluminum is flexible, corrosion resistant; it keeps high dimensional equilibrium with thin walls and may be utilized in just about any business.

Aluminum Die Casting Software:

-

- Aluminum castings improve automotive fuel efficiency by leading to weight reduction demands

- Aluminum can be used in a broad Assortment of infrastructure and networking supplies in the telecom and computing businesses since RF filter boxes and housings demand heat dissipation

- In handheld devices, aluminum castings Offer EMI/RFI protecting, rigidity, and durability with minimal amount

- Due to aluminum’s outstanding electrical performance and protecting properties, even at high-temperature surroundings, die cast aluminum is Perfect for electronics and housings